The Syst-A-Matic Team Looks Ahead to Get It Right, Every Time

Syst-A-Matic achieves customer satisfaction by delivering the highest quality work to print specification, on time, within budget and without defects. The Syst-A-Matic team has the expertise and experience needed to avoid and resolve the problems that can delay shipment, cause budget overruns or rejected parts. Strategically located in northwestern Pennsylvania, Syst-A-Matic is a leader in tooling, machining and advanced manufacturing in the Meadville area. Syst-A-Matic offers a wide range of services and a logistical advantage for serving customers in the United States and Canada.

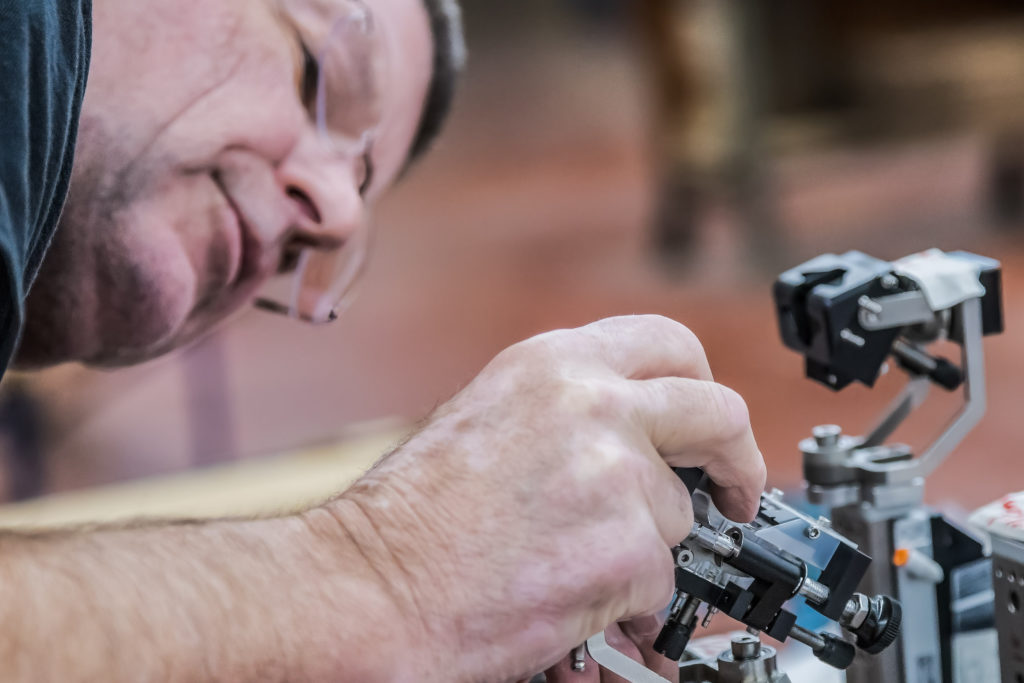

Our Attention to Detail Means More Value for Our Customers

With each order, the Syst-A-Matic team carefully reviews the prints to ensure that every aspect of the project will result in a perfect fit – this review is critical for the production of small to medium parts that are designed to integrate within a larger system or process.

“Build-to-print” means more than delivering what was ordered. It means that the work will be delivered with precision accuracy. According to Ken Miller, Syst-A-Matic President, “On the rare occasion, we have a problem, we immediately correct it. What we find is that if customers schedule the time to allow us to pre-assemble parts supplied by others along with a prototype of the parts we produce before we begin the final project, we can correct any drawing errors, or point out an inconsistency before we proceed with the work.”

This initial quality check eliminates waste in terms of rejected parts, additional cost and delivery delays. The team acts as a consultative partner by using their experience to make recommendations during the design process and offering updates on order progress. This saves cost and reduces labor prior to proceeding with each order, often saving customers time and money.

A Range of Services for Every Machining Need

Taking the time to look ahead to ensure a perfect fit for each customer is what sets Syst-A-Matic apart, and it’s the reason customers return year after year. With over 40 years of experience working with customers from large international companies to small, local suppliers, Syst-A-Matic offers these quality services:

- Precision Machining

- Welding

- Tool Making

- Prototyping

- Assembly

- Painting

- Vertical Milling

- Precision Grinding

- Turning

- Laser Mark

- Wire EDM

- Reverse Engineering

- Horizontal Milling

- Fabrication

- CNC Turning & Milling

- Honing

- Jig Grinding

Other Unique Services a Quick Drive Away

Syst-A-Matic works with manufacturing partners in the surrounding area to offer additional services. With such a variety of services within a short drive, Syst-A-Matic is able to develop and maintain local relationships to provide benefits for their customers. These local services include:

- Material Supplies

- Heat Treating

- Black Oxide

- Electroless Nickel

- Anodizing

- Flash Chrome

- Armoloy

- Tin Coat

- Zinc Plating

- Welding

- Electrical Services

- Casting

- Forging

- Powder Coating

- Certification for Materials & Plating

- Metrology Services Available

- RAM EDM

Depending on your unique needs, we can help you utilize these services to make sure your project is produced with quality and on time.

We’re Ready to Help You

With detailed document reviews, thorough quality assurance checks, a variety of internal services and a central location to many other unique resources, it’s no wonder why so many companies come to us for their tooling needs. If you’re interested in more information or to request a quote for your next project, contact us, call 814-336-1026 or email sales@syst-a-matic.com.